How Contingency Calculation Is Different Before and After the Final Investment Decision

During a project development phase, estimating uncertainty will typically decrease as project maturity increases. At the same time, the estimates will include some contingency. What are the expected levels of uncertainty and contingency, and how to evaluate them in a mutually exclusive manner? Why is the approach different from the project execution phase? Our new White Paper 2024-06 ‘Managing Contingency and Uncertainty During Early Project Estimates: How Contingency Calculation Is Different Before and After the Final Investment Decision’ delves into more detail on the issue of contingency and uncertainty evolution during project development, and the differences with project execution.

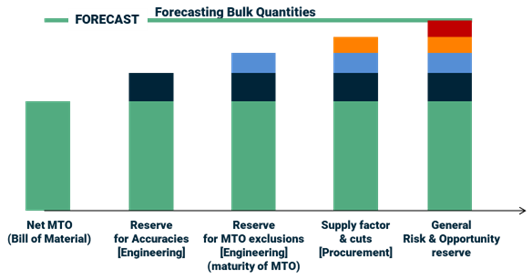

During the project development phase, the uncertainties need to be considered carefully, based on experience, to ensure that expectations are managed as to the final estimate at Final Investment Decision. The contingency element included in the base estimate must be focused on identified risks, and the uncertainty element estimated separately based on project development stage and benchmarks.

At this stage, it is important that the elements included in both uncertainties and contingency are mutually exclusive, to avoid double dipping.

When in execution phase, contingency generally includes both elements of discrete risks and more systemic risks and uncertainties, therefore the basis of calculation will change. This is not always fully understood and needs to be carefully communicated to the decision-maker to make sure the project remains well protected against unexpected events.

Read our new White Paper 2024-06 ‘Managing Contingency and Uncertainty During Early Project Estimates: How Contingency Calculation Is Different Before and After the Final Investment Decision’ to better understand the definitions and usage of uncertainties and contingency at various stages of the project.

If you can’t access the link to the white paper, copy and paste the following link in your browser: https://www.projectvaluedelivery.com/_library/2024-06_contingency_vs_uncertainty_v0.pdf